Injection Moulding

Prototypes are most useful when they’re made from the same plastic as the final production part, but it’s hard to justify the cost of creating injection moulded prototypes when they require the same expensive, time consuming tooling as production parts. Typically only a short run of parts is required and they are required quickly in order to validate the design.

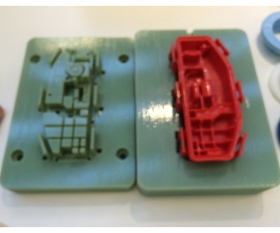

3D printing your prototype moulds in-house with a Stratasys PolyJet 3D printer offers a fast, affordable way to produce injection moulded prototypes in small quantities. Designers and engineers can test their work more frequently and more accurately, and so the product can go into production with greater confidence.

WHITE PAPER

WHITE PAPER